Being a family business, AGRO stands for future thinking in everything we do. We exclusively use raw materials, which comply with our own high purchasing standards and which are accurately examined before processing. A good proportion of the wire being processed has well-known provenance because it originates from the plant of our sister company, AGRO Steel Wire, on the same site. When a new order is being processed every machine is calibrated by our qualified employees. The first innersprings of each new order are carefully examined to ensure quality control. Beside this, AGRO springs and innerspring units are regularly checked during production against a number of different parameters. With our special labeling system – which gives information about date, time, machine and order number – we are able to give full traceability to the whole production process at any time. This certified quality management process creates transparency and reliability – and makes our innersprings the ideal basis for your high quality final products.

AGRO – quality „Made in Germany“

- DIN EN ISO 9001 quality management

- LGA quality certificates for all groups of AGRO products

- OEKO-TEX® STANDARD 100, annex 6, product class I (certificate: 10.0.77270)

- DIN EN ISO 50001 energy management

- DIN EN ISO 14001 environmental management

LGA quality certificates – tested on four features:

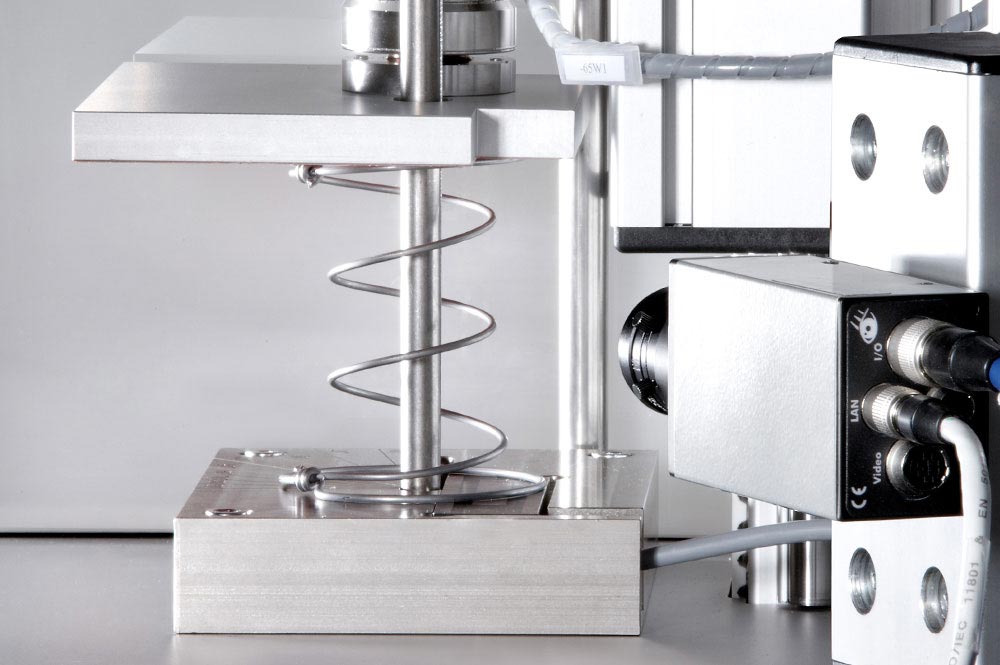

- Fatigue test / Rolling test

- Material suitability

- Quality assurance